Compact Web Guiding Systems

-

Availability:8 Weeks Lead Time

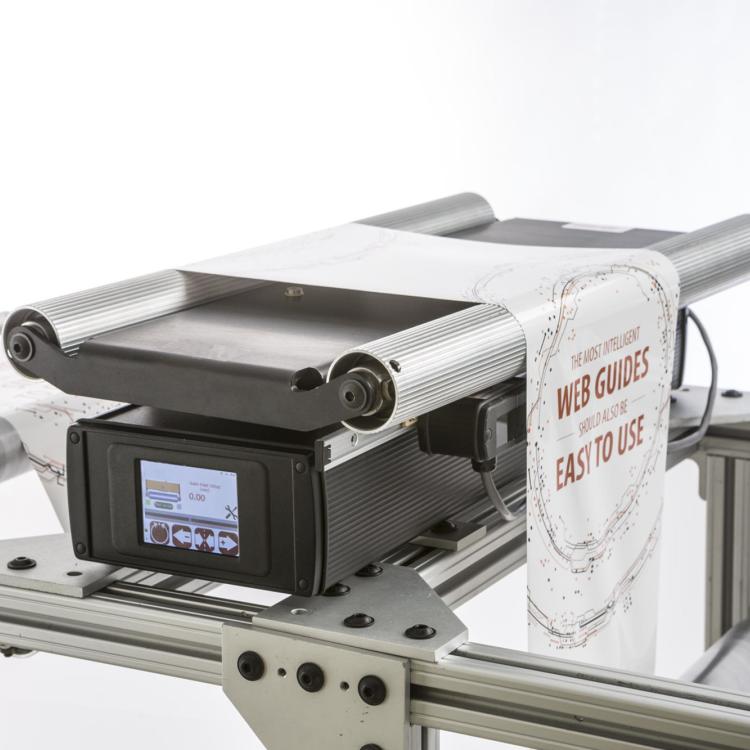

Most Intelligent WEB GUIDES should be EASY TO USE!

Simplify your setup without sacrificing accuracy

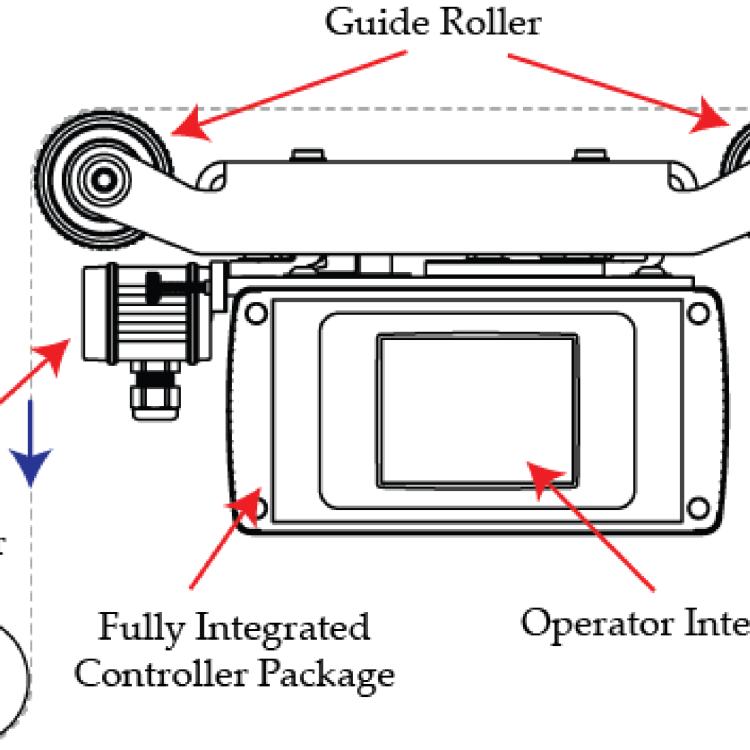

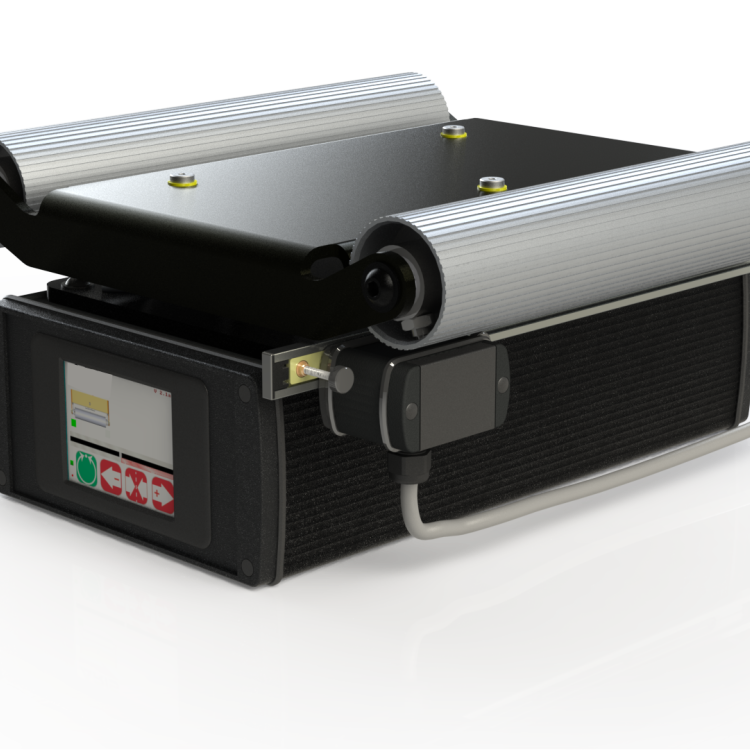

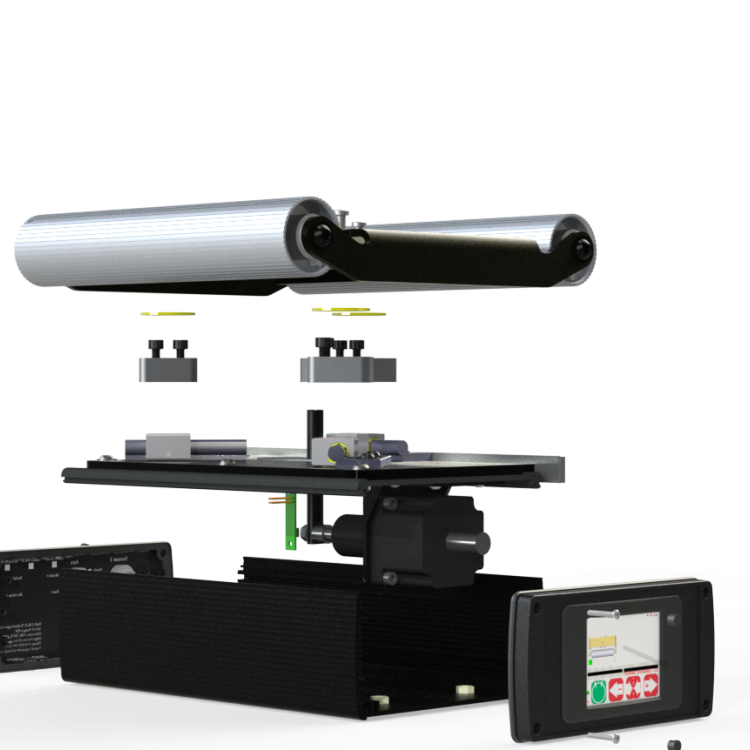

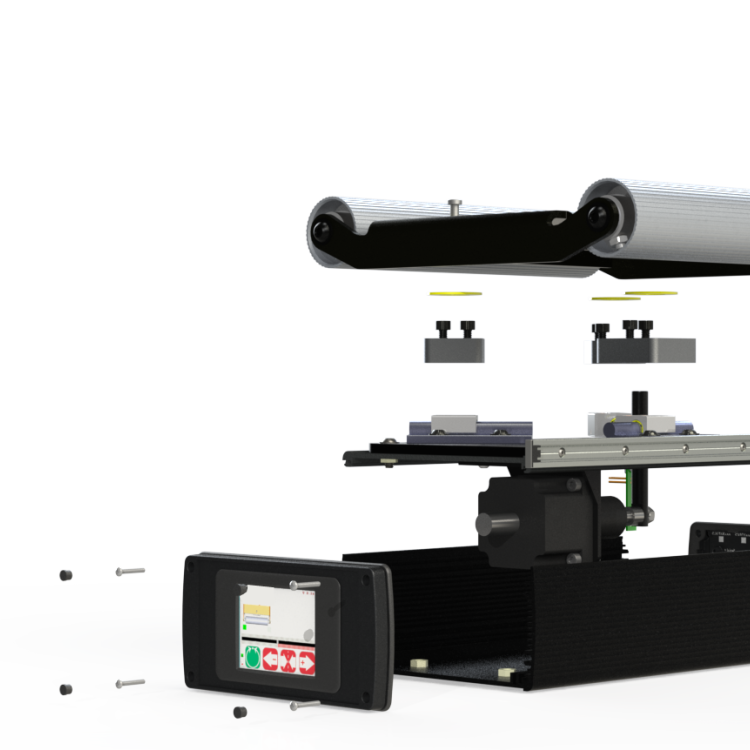

The Roll-2-Roll Web Guide is the simplest web guide available in the market. The fully integrated solution includes a web guide mechanism mounted on an enclosure housing the actuator, controller and operator interface. The plug-and-play web guiding system can be installed out-of-the box within 10 minutes. The web guide requires no subsequent setup or calibration once installed, even if the materials and processes change.

Roll-2-Roll sensor and control technology makes the web guide easy to install, and simple to operate and maintain. The accurate and precise measurement technology adjusts automatically to the physical characteristics of the material, such as opacity and porosity. The benefits include reduction of waste, downtime and changeover time.

No Setup + No Calibration = No Worries

Simple and easy solution

- Increase productivity with no setup and calibration after product changeover

- Save time with plug-and-play operation

- Reduce waste with high accuracy and high precision guiding

- Save money with a single solution for multiple guiding applications

- Fully integrated solution with integrated actuator, operator interface and controller for simple installation

- A sensor that adapts automatically to any material helps decrease downtime

- Grooved rollers for improved traction and guiding performance

- Linear hybrid stepper motor with high dynamic response and positioning accuracy for superior performance to minimize waste

- Low voltage and safe operation with 24 VDC power input

- Fully integrated package for quick and easy installation

- Color touchscreen operator interface with language independent icons for easy adoption in multiple regions

- Six sizes from 250 mm (10") to 550 mm (22") for any narrow web converting application

- Narrow web printing, coating, lamination and slitting

- Diaper, adult incontinence and feminine hygiene product converting

- Edge guiding, center guiding, line guiding and contrast guiding

| Roller Face | 250, 300, 375, 425, 500, 550 mm | Nominal Travel | ± 27 mm |

| Nominal Temperature | 0 - 60° C | Correction Rate | Up to 135 mm/sec |

| Motor Type | Linear Hybrid Stepper | Operator Interface | Color touchscreen |

| Input Supply | 24 VDC | Languages | Language Independent |

| Control Frequency | 50 Hz - 200 Hz | Sensor Type | Fiber Optic |

| Error Frequency | 2 Hz - 8 Hz | Sensor Resolution | 0.0635 mm or 0.125 mm |

| Maximum Tension | 225 N | Sensor Range | 16, 48, 221 or 440 mm |

| Linear Force | 250 N - 1000 N | Accuracy | >99.2% |

| Options | Description |

|---|---|

| WMS G250-50-NC | Web guide mechanism: 50 mm diameter, 250 mm wide roller |

| WMS G300-50-NC | Web guide mechanism: 50 mm diameter, 300 mm wide roller |

| WMS G375-50-NC | Web guide mechanism: 50 mm diameter, 375 mm wide roller |

| WMS G425-50-NC | Web guide mechanism: 50 mm diameter, 425 mm wide roller |

| WMS G500-50-NC | Web guide mechanism: 50 mm diameter, 500 mm wide roller |

| WMS G550-50-NC | Web guide mechanism: 50 mm diameter, 550 mm wide roller |