Controlling the web requires accurate and precise web position measurement. In inaccuracies in the sensor measurement leads to increased waste and downtime.

Existing Sensors and Sensing Principle

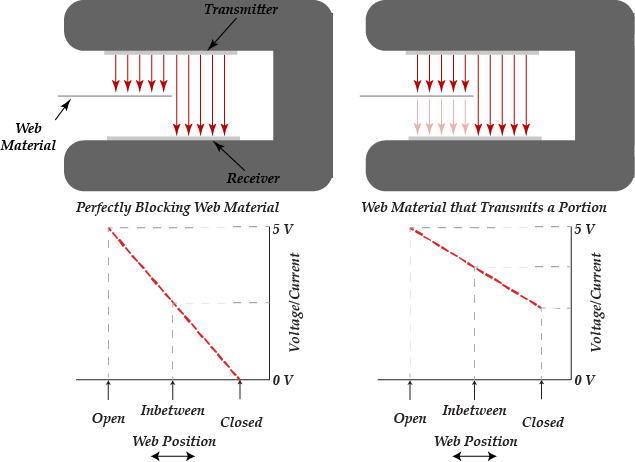

Opposing mode or through beam sensing mode sensors are the most common sensors used for web edge detection. These U-shaped or fork-shaped sensors have one arm to transmit the sensing signal while a pre-aligned receiving arm collects the transmitted signal. The web material that is passed between the two sensor arms blocks the signal and the receiver arm collects the portion of the signal unblocked. In ideal cases the amount of signal received is proportional to the percentage of the signal blocked by the web material, thereby the web position can be inferred.

The signal used in this sensing principle may be light (visible or infrared), sound (ultrasonic) or air (pneumatic). Often the choice of sensor used for a particular application depends on the material. The material dependent property of the sensor is the main drawback of this simple sensing principle. Whenever a particular material allows a portion of the signal to pass through the web material the sensor accuracy is affected. As illustrated below both slope and bias (linearity) of the sensor output is affected by materials that transmit the sensor signal. To compensate for this error the sensor needs to be calibrated to improve the accuracy of the output. However, with certain materials no amount of calibration may lead to a satisfactory output for the type of sensing signal.

Roll-2-Roll Technologies Web Position Sensor Working Principle

Scattering

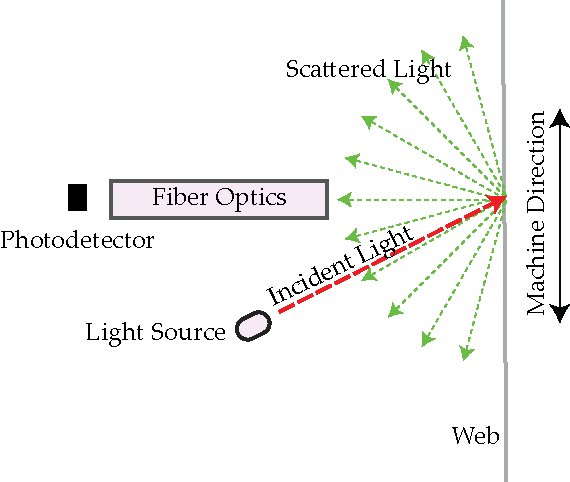

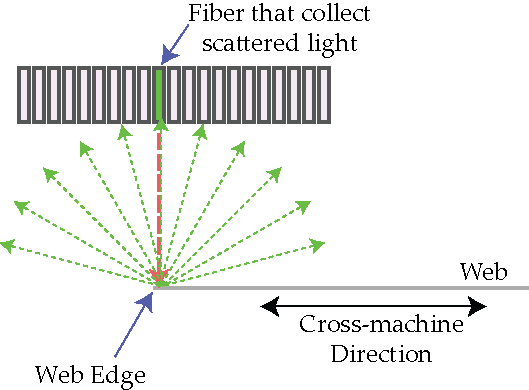

Any material opaque, transparent, translucent, porous or nonwoven material will scatter light incident on them. The amount of scattering depends on the material properties such as roughness of the material, wavelength of incident light, refractive index (for transparent material), among other properties. Roll-2-Roll Technologies WPS relies on the property that some amount of light will be scattered by any material. A light source, such as laser or LED is used to illuminate the area near the edge of the web. As the light falls on the web, the light is scattered in all directions. By collecting the light scattered from the web material the position of the web edge is determined.

Spatial Filtering

The light transmitting properties of the optical fibers is enabled by the principle of total internal reflection. The total internal reflection occurs due to the change in refractive index of the core and cladding within the optical fibers. This property of the optical fibers also result in the fibers acting as spatial filters.

Roll-2-Roll Technologies WPS uses the spatial filtering properties of fiber optics to filter the scattered light from the web surface. Since the fiber optic array is directionally sensitive, light is spatially filtered in a way that only fiber(s) directly inline with the scattered light are illuminated. All other fibers do not couple light since the scattered light falls on them at an angle greater than the critical angle. The spatially filtered light is projected onto a one dimensional line scan camera and the image recorded by the camera is processed using advanced digital signal processing algorithms to accurately detect the position of the material.

Any material, such as opaque, transparent, porous or nonporous, scatters (or reflects) light. Therefore, the sensor is not affected by the material properties. The intelligent digital signal processing automatically adapts to any changes in the amount of scattering to provide a true, absolute measurement.

Comparison of Roll-2-Roll Technologies Web Position Sensor and other sensing technologies

Advantages of Roll-2-Roll® Sensor sensing principle

The sensing principle is unaffected by the material properties. This enables the sensor to require no setup or calibration. Additionally, by changing the wavelength and the angle of the incident light, the position of a contrasting feature on the web such as a colored line can be detected.

| Sensor Characteristics | Roll-2-Roll WPS | U-Shaped Infrared | U-Shaped Ultrasonic | U-Shaped Pneumatic | Camera or Vision System |

| Unaffected by Opacity | ✔ | ✘ | ✔ | ✔ | ✘ |

| Unaffected by Porosity | ✔ | ✔ | ✘ | ✘ | ✔ |

| Unaffected by Splices | ✔ | ✘ | ✘ | ✘ | ✔ |

| Unaffected by Dust | ✔* | ✘ | ✘ | ✔ | ✘ |

| Unaffected by Temperature Change | ✔ | ✔ | ✘ | ✔ | ✔ |

| Unaffected by Vacuum | ✔ | ✔ | ✘ | ✘ | ✔ |

| Unaffected by Ambient Light | ✔ | ✔ | ✔ | ✔ | ✘ |

| Unaffected by Vibration or Ringing | ✔ | ✔ | ✘ | ✔ | ✔ |

| Analog or Digital Measurement | Digital | Analog | Analog | Analog | Digital |

| Line Detection | ✔ | ✘ | ✘ | ✘ | ✔ |

| Contrast Detection | ✔ | ✘ | ✘ | ✘ | ✔ |

| Resolution Unaffected by Range | ✔ | ✘ | ✘ | ✘ | ✘ |

| Automatic Calibration | ✔ | ✘ | ✘ | ✘ | ✘ |

* The dust issue can be reduced by using intelligent digital processing algorithms.

As we search for the most appropriate equipment for our operation, we are faced with the task of selecting from myriad options based on technical data and specs. Through these data, measurements of accuracy, precision, linearity and resolution, manufacturers are trying to present the benefits of their products based on the device’s performance profile. However, sometimes what appears to be the best offer, based on what looks to be the best technical data, might not really be the best. The technical data can even be irrelevant information when considering performance. See performance indicators relevant to your system and how to apply this information to your applications.